A Cooling System is a Critical Plant Utility

Just like your plant electrical system, telecommunications equipment, or data network infrastructure, a process cooling water failure can shut down a facility and may even involve safety issues. Let’s outline some of the steps you can take to minimize downtime.

Avoiding Trouble

Most cooling system failures are not catastrophic, merely expensive and disruptive. The most common problem is fouling — accumulated dirt, debris, products of corrosion, mineral scale and bio-films that coat heat transfer surfaces.

- Buy equipment that is cleanable and easy to maintain.

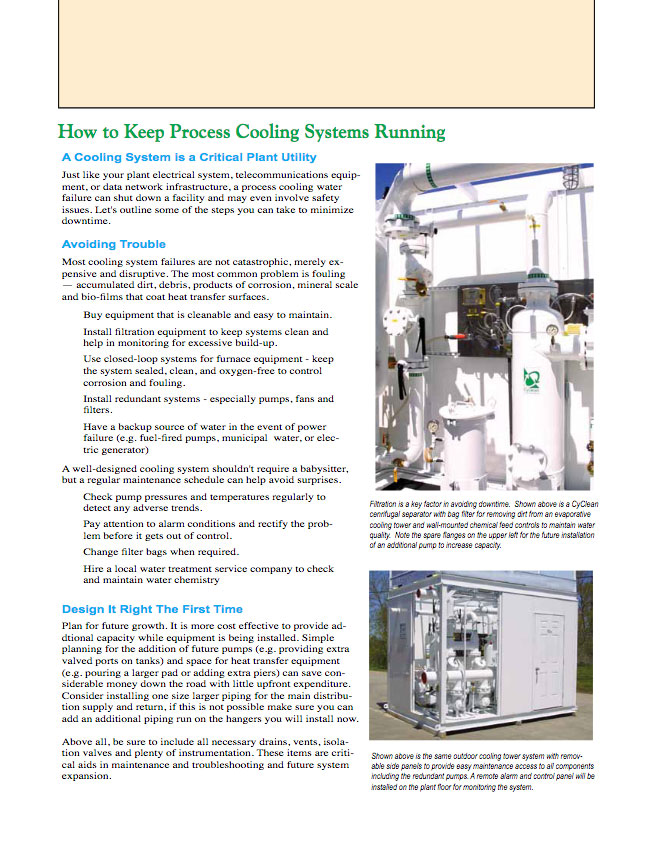

- Install filtration equipment to keep systems clean and help in monitoring for excessive build-up.

- Use closed-loop systems for furnace equipment – keep the system sealed, clean, and oxygen-free to control corrosion and fouling.

- Install redundant systems – especially pumps, fans and filters.

- Have a backup source of water in the event of power failure (e.g. fuel-fired pumps, municipal water, or electric generator)

A well-designed cooling system shouldn’t require a babysitter, but a regular maintenance schedule can help avoid surprises.

- Check pump pressures and temperatures regularly to detect any adverse trends.

- Pay attention to alarm conditions and rectify the problem before it gets out of control.

- Change filter bags when required.

- Hire a local water treatment service company to check and maintain water chemistry

Design It Right The First Time

Plan for future growth. It is more cost effective to provide addtional capacity while equipment is being installed. Simple planning for the addition of future pumps (e.g. providing extra valved ports on tanks) and space for heat transfer equipment (e.g. pouring a larger pad or adding extra piers) can save considerable money down the road with little upfront expenditure. Consider installing one size larger piping for the main distribution supply and return, if this is not possible make sure you can add an additional piping run on the hangers you will install now.

Above all, be sure to include all necessary drains, vents, isolation valves and plenty of instrumentation. These items are critical aids in maintenance and troubleshooting and future system expansion.